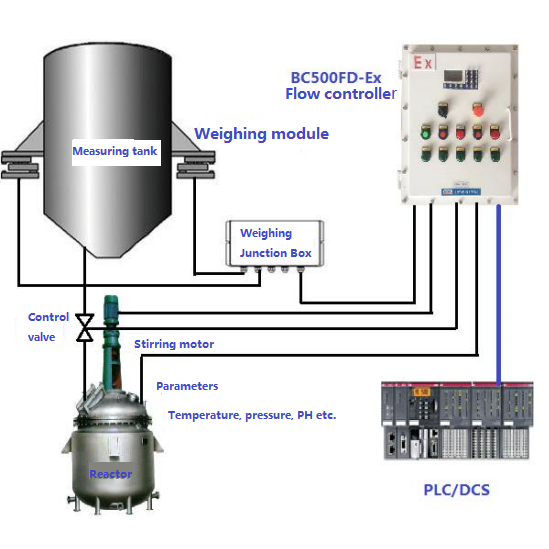

JJ-LIW BC500FD-Ex Dripping System

Awọn ilana iṣẹ

Oluṣakoso mita n gba awọn ifihan agbara iwuwo ti ojò wiwọn ni akoko gidi

Ṣe iyipada iwuwo fun akoko ẹyọkan sinu ṣiṣan lẹsẹkẹsẹ

Adarí PID ṣe iṣiro oṣuwọn sisan lẹsẹkẹsẹ ati iye tito tẹlẹ

Gẹgẹbi awọn abajade algoridimu PID, oluṣakoso mita n ṣe awọn ifihan agbara afọwọṣe 4-20mA si àtọwọdá ti n ṣatunṣe / oluyipada lati ṣe iṣakoso ṣiṣan deede

Ni akoko kanna, oluṣakoso mita n ṣajọpọ iwuwo ti ohun elo ti n ṣan jade lati inu ojò wiwọn. Nigba ti iye akojo jẹ dogba si iye ti a ṣeto, oludari mita naa tilekun àtọwọdá / ẹrọ oluyipada ati ki o da idaduro naa duro.

Awọn ẹya ara ẹrọ

Ṣe afihan wiwo ifihan, ṣafihan ṣiṣan lẹsẹkẹsẹ ati lapapọ lapapọ

Iṣẹ ifunni aifọwọyi

Latọna jijin, iyipada agbegbe, ati afọwọṣe ati iṣakoso adaṣe

Abojuto ipo okeerẹ ati iṣẹ itaniji pq

Abojuto akoko gidi ti fifuye sensọ, rọrun fun itọju ati laasigbotitusita

Le ipoidojuko pẹlu DCS/PLC nipasẹ awọn data akero

Standard RS232/485 meji ni tẹlentẹle ebute oko, MODBUS RTU ibaraẹnisọrọ

Ṣe afikun titẹ sii 4 ~ 20mA ati iṣelọpọ 4 ~ 20mA Aṣayan Profibus DP Iyan

Awọn ẹya ara ẹrọ

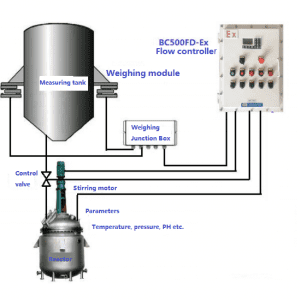

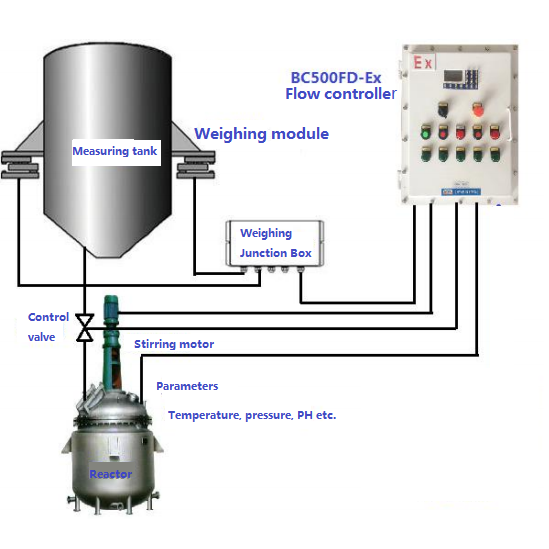

Ọran 1: Wiwọn flowmeter

1. Ọna wiwọn ko ni ipa nipasẹ iwọn otutu, iwuwo, ọna fifi sori ẹrọ, ati bẹbẹ lọ.

2. Iwọn wiwọn giga

3. Ko si olubasọrọ pẹlu awọn ohun elo, ko si agbelebu-ikolu

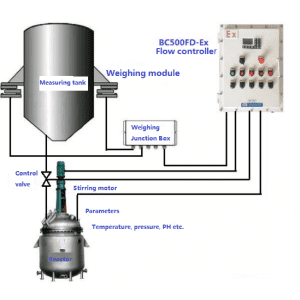

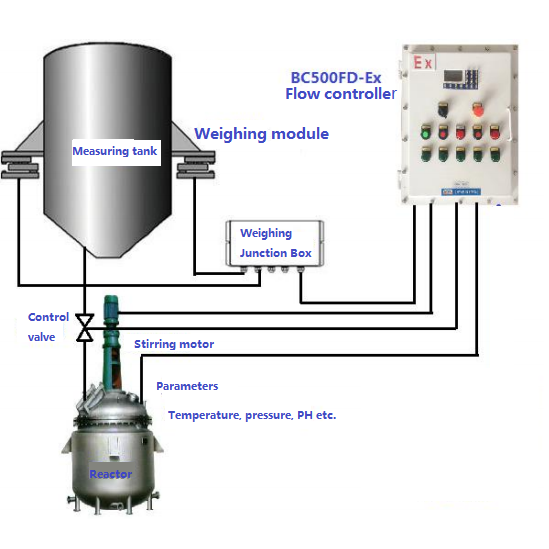

Ọran 2: Iṣakoso aifọwọyi ti sisọ nipasẹ ohun elo

1. Laifọwọyi drip Iṣakoso ti awọn irinse

2. Awọn ọna eto ti awọn paramita ilana

3. Ifihan iṣẹ lori aaye, rọrun ati ogbon inu

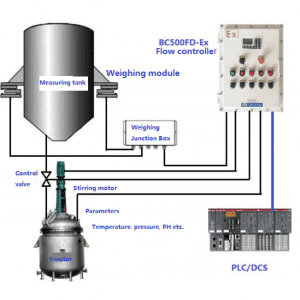

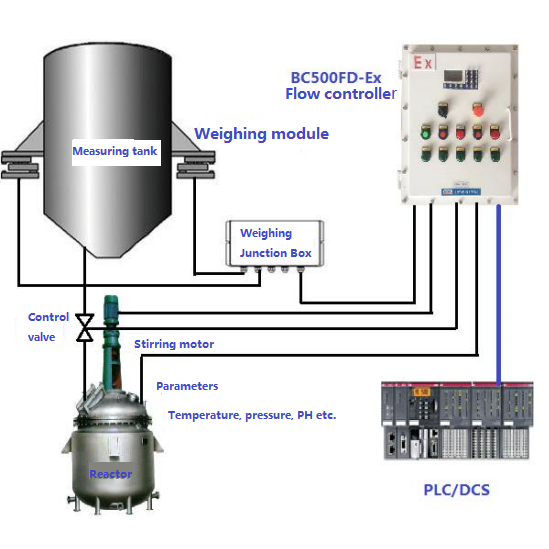

Ọran 3: Ṣiṣan mita mita, ṣiṣan iṣakoso DCS

1. Ọna wiwọn ko ni ipa nipasẹ iwọn otutu, iwuwo, ọna fifi sori ẹrọ, ati bẹbẹ lọ.

2. Mita taara pese data sisan, ati DCS n ṣakoso ilana naa

3. Iyara iṣapẹẹrẹ igbohunsafẹfẹ ati iwọn wiwọn giga

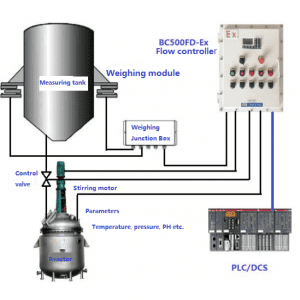

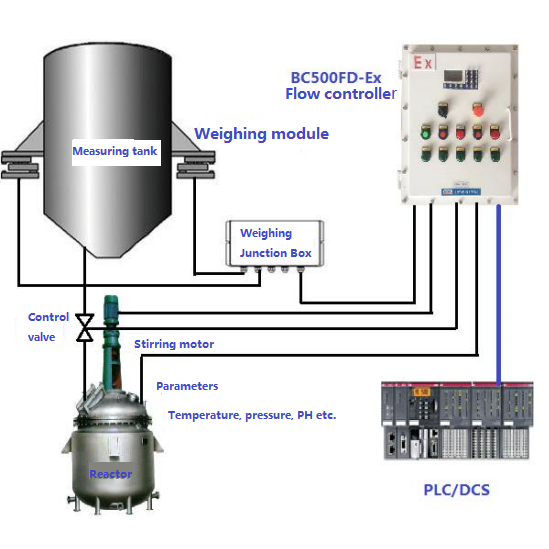

Ọran 4: Ilana DCS, mita n ṣakoso ṣiṣan ni aifọwọyi

1. Laifọwọyi sisu Iṣakoso

2. Ohun elo naa ṣe alabapin ninu ilana naa

3. Din iye owo ti PLC/DCS software ati hardware

Sipesifikesonu

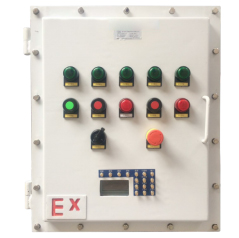

| Apade | Simẹnti Aluminiomu |

| Ṣiṣe Ipo | Ifunni igbagbogbo, Iwontunwọnsi ipele ohun elo, ifunni ipele |

| Iwọn ifihan agbara | -20mV~+20mV |

| O pọju. Ifamọ | 0.2uV/d |

| FS fiseete | 3ppm/°C |

| Ìlànà | 0.0005% FS |

| Flowrate Unit | kg/h, t/h |

| Ojuami Dec | 0, 1, 2, 3 |

| Ipo Iṣakoso | Agbegbe Adj. / PID Adj. |

| O pọju opoiye | <99,999,999t |

| Ifihan | 128x64 Yellow-Green OLED àpapọ |

| Bọtini foonu | 16 Alapin yipada awo pẹlu tactile-lero awọn bọtini; poliesita agbekọja |

| Oye I/O | 10 Awọn igbewọle; Awọn abajade 12 (24VDC @ 500mA pẹlu aabo fifuye pupọ) |

| Afọwọṣe Ijade | 4 ~ 20mA/0 ~ 10V |

| USART | COM1: RS232;COM2: RS485 |

| Serial Protocol | MODBUS-RTU |

| Ibi ti ina elekitiriki ti nwa | 100~240VAC,50/60Hz, <100mA(@100VAC) |

| Awọn iwọn otutu ti nṣiṣẹ | --10°C ~ +40°C, ọriniinitutu ibatan: 10% ~ 90%, ti kii-condensing |